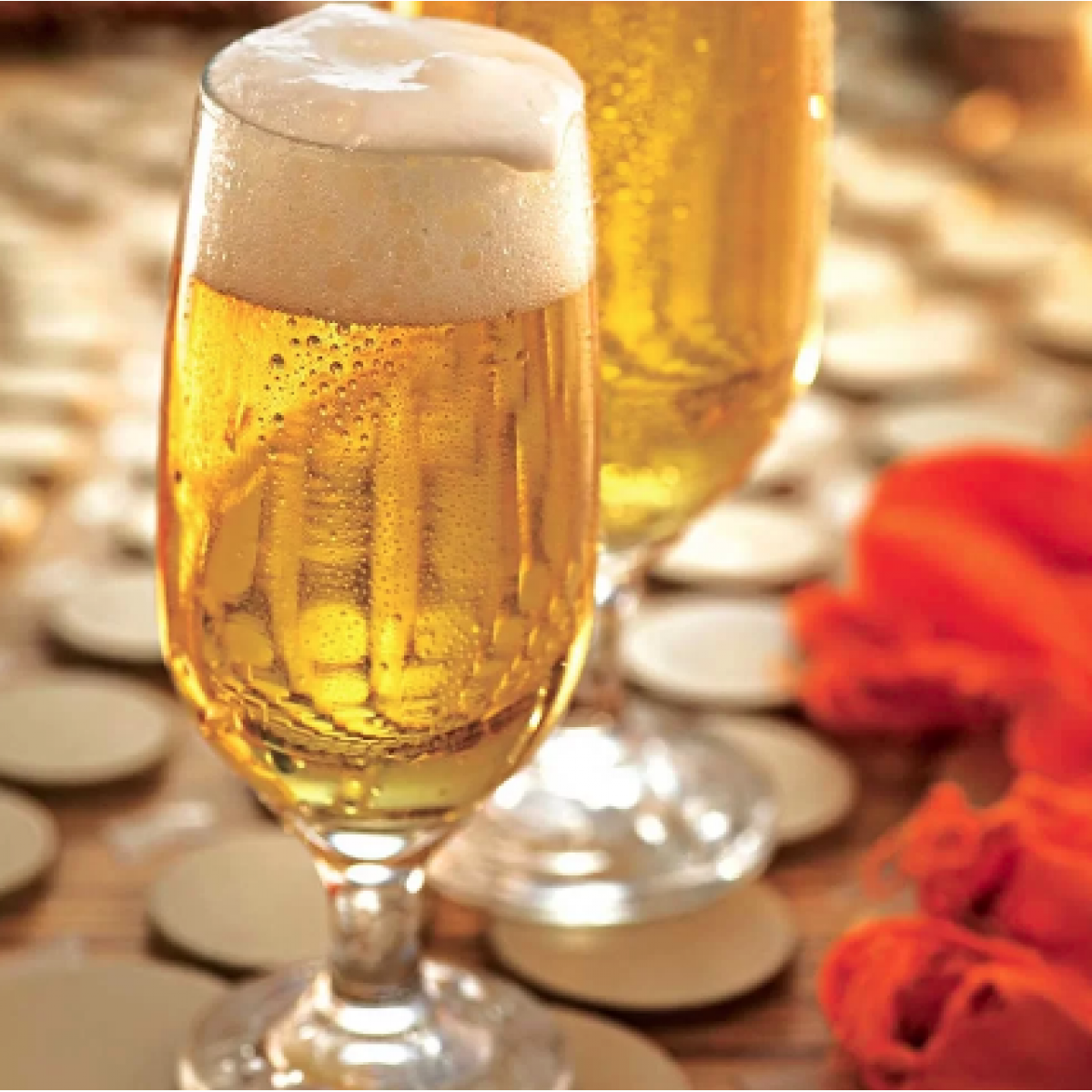

Jogo de Taças de Cerveja Floripa 300ml com 6 Unidades Nadir Figueiredo |Maravilhas do Lar - Jogo de Taças de Cerveja Floripa 300ml com 6 Unidades Nadir Figueiredo - Nadir Figueiredo

Taça Floripa Cerveja em vidro 300Ml (unidade)- Nadir - Nadir Figueiredo - Taça de Cerveja - Magazine Luiza

Jogo de Taças de Cerveja Floripa 300ml com 6 Unidades Nadir Figueiredo |Maravilhas do Lar - Jogo de Taças de Cerveja Floripa 300ml com 6 Unidades Nadir Figueiredo - Nadir Figueiredo